Технология длинноволокнистого термопластика (LFT) продолжает развиваться. В то время как автомобильные приложения сохраняют свое доминирующее положение на рынке, другие отрасли промышленности все больше привлекают обещания легкого веса и высокой прочности - например, полипропиленовые компаунды LFT могут предлагать более дешевые альтернативы металлам, а также более дорогие технические инженерные полимеры.

Непрерывное проникновение компаунда LFT PPв автомобильной сфере

Согласно отчету, опубликованному AMI Consulting в сентябре 2021 года, проникновение на рынок полипропилена продолжает расти. В отчете содержится количественная оценка использования LFT PP в гранулированной форме (LDT-G) и композитного LFT PP (LDT-D), а также отслеживается использование по всему миру. LFT PP широко используется в автомобильных передних креплениях, креплениях приборной панели, дверных панелях, консолях, педалях, щитках днища и многих других автомобильных приложениях, говорится в сообщении компании. Одной из особенностей этих применений является то, что LFT PP заменяет сталь, тем самым снижая вес, или более дорогие инженерные пластмассы.

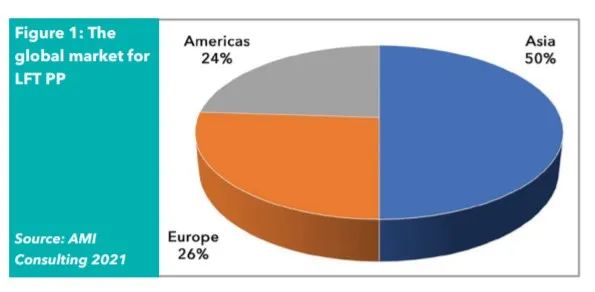

AMI Consulting прогнозирует, что LFT PP будет поддерживать устойчивый рост до 2025 года. Хотя темпы роста варьируются в зависимости от сегментов приложений, OEM-производителей автомобилей и географических рынков. В прошлом Европа была лидером по продажам LFT, но сейчас все изменилось. Согласно отчету, в 2020 году на Азию придется 50 % мирового спроса на полипропилен LFT по сравнению с 26 % в Европе и 24 % в Америке (таблица 1).

Таблица 1: Распределение мирового рынка LFT PP за последние 20 лет

One of the fastest growing application areas is lift doors for car trunks, which range in design from all metal to almost no metal. In metal-free designs, LFT PP is used to provide structural strength and is complemented by high performance PP to provide a paintable exterior skin. In the most demanding applications, the LFT PP elements within the structure are exposed and therefore require a good aesthetic finish. Plastic lift doors are especially valuable to electric car makers as a new way to reduce weight.

The shift to electric and hybrid vehicles, while threatening some existing polymer applications, is also creating new opportunities for LFT PP as designers are rethinking concepts and adopting new approaches. The report cites the example of Tesla's "frunk" -- a back-up or storage compartment located at the front. This would make use of space in the front of the vehicle for storage, but would need to be designed with the ability of a traditional car's front end to absorb the impact of a crash.

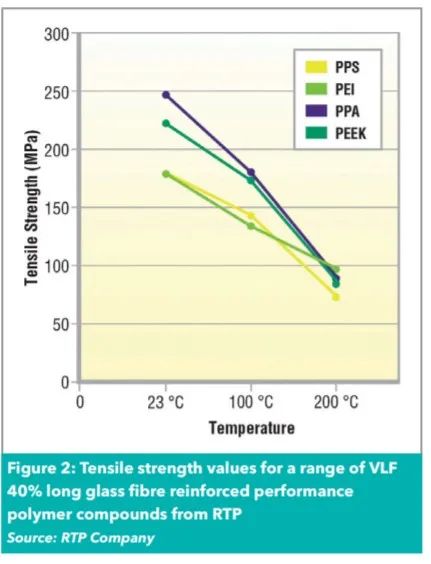

The strong interest in LFT materials from various industries is confirmed by RTP Inc., which offers a wide range of LFT materials. "Replacement metal parts or over-engineered short fiberglass compounds continue to be major growth opportunities," said Zach Halverson, Manager of the company's structured products business. For example, long fiber polypropylene compounds can often successfully replace short glass fiber polyamide compounds to provide a lower cost and lower density solution." Long fiber technology in engineering and high performance based polymers such as PEEK, PPA, PEI and PPS, these combine the desired mechanical and thermal properties of the polymer with the added benefit of long fibre reinforcement. They are said to be a good alternative to metals in particularly demanding environments, such as in the oil and gas industry, where other materials cannot meet demand (Table 2)

Table 2: Long glass fiber reinforced polymer compounds with tensile strength range of 40%.

Halverson said the automotive industry remains the largest consumer of long-fiber thermoplastics, and any changes in the industry will affect its use.

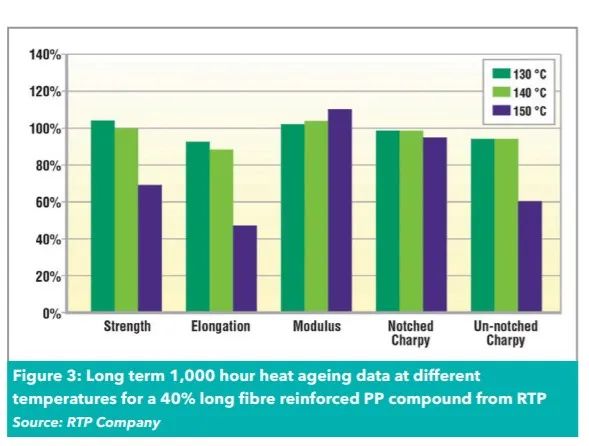

As the primary end user of LFT, the performance needs of the automotive industry are a key driver of LFT development. Current challenges include increasingly stringent VOC limits, the ability to withstand long-term thermal aging of more than 1,000 hours at 150°C (Figure 3), stronger UV-resistant linearity, and the ability to achieve A highly aesthetic Class A surface finish directly outside the mold. Usually several of these requirements need to be met in an application process.

Figure 3: Long-term 1,000-hour thermal aging data of 40% long fiber reinforced PP composites from RTP at various temperatures.

To address these automotive challenges, Xiamen LFT composite plastic Co.,ltd's product development team is constantly experimenting with extensive experimental combinations of new formulations, and developed anti - UV grade products.

Long fibre technology is now a mature area of the thermoplastic market. Nearly 40 years have passed since long fibre reinforced thermoplastics were first introduced in the early 1980s. So the industry is definitely at or reaching a stage of maturity, particularly in commodities for materials such as long glass fibre polypropylene, where it has a large number of suppliers. Most market research reports indicate that the long fiber materials market will continue to grow at a high single-digit CAGR for the foreseeable future. Growth has been prominent in the automotive industry, where long fibre materials are valued for their lightweight capabilities in metal replacement scenarios. The growth in material use has coincided with an increase in the global production of cars and trucks. Transportation is not the only market segment focusing on weight loss. Consumer discretionary products, especially sports and industrial equipment, are moving toward more portable devices that make life easier for users. While lightweight is often the first choice for product designers, the change to metal composites offers many other benefits. Cost reduction is a major driver, easily achieved when switching from metal manufacturing to injection molding production. The metal-like properties of long fiber composites, combined with their excellent durability, can also produce very strong products. These products are also usually made with recycling capabilities in mind. In a world increasingly concerned with the life cycle of materials, this is a necessary consideration.

LFT is valued for its lightweight and strength in applications such as off-road vehicles.