новый блог

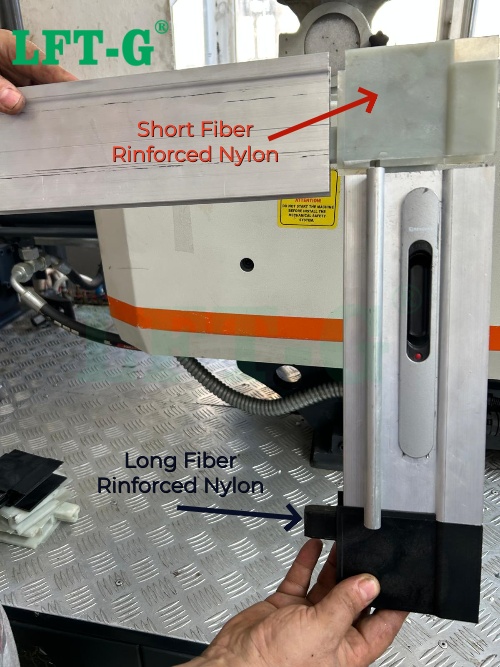

В этом проекте для замены материала, армированного коротким стекловолокном, в торцевом опорном блоке позиционирующего упора станка для резки алюминиевого профиля был выбран ПА6, наполненный 40% длинным стекловолокном (ПА6-LGF40). Чёрный компонент служит структурной опорой, требующей высокой механической прочности, размерной стабильности и длительной устойчивости к многократным ударам и вибрации.

Позиционный упор станка для резки алюминиевого профиля играет решающую роль в обеспечении точности и стабильности резки. Традиционно концевой упор изготавливался из короткого нейлона, армированного стекловолокном, который часто деформировался, изнашивался и терял точность после длительного использования из-за постоянной вибрации и ударов во время работы.

Чтобы повысить долговечность и сохранить размерную стабильность, клиент искал решение, которое сочетало бы в себе высокую прочность, жесткость и долговременную надежность без увеличения веса или ухудшения технологичности.

PA6-LGF40 продемонстрировал следующие ключевые преимущества:

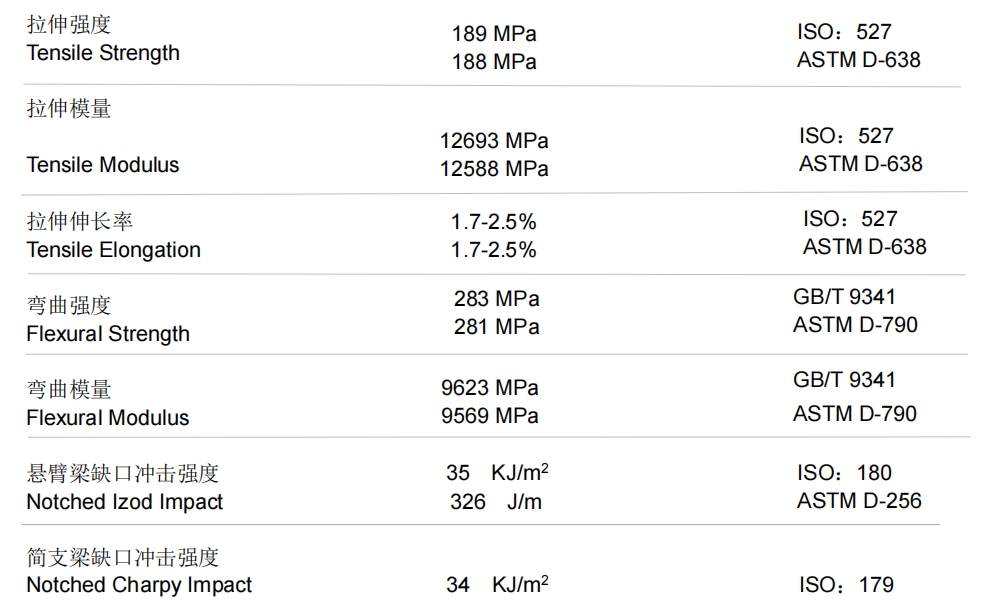

Техническое описание для LFT PA6-LGF40

Переключившись на ПА6-ЛГФ40 заказчик получил высокопроизводительный конструктивный элемент, который обеспечивает превосходная механическая прочность, ударопрочность и размерная стабильность по сравнению с предыдущим коротким стекловолоконным материалом.

Повышенная прочность и длительный срок службы позиционного упора обеспечивают стабильная точность резки, уменьшение деформации и более длительный срок службы оборудования.

Кроме того, значительно повысилась износостойкость и надежность снижение частоты технического обслуживания и общих эксплуатационных расходов , сохраняя при этом малый вес.

Этот проект демонстрирует успешную замену короткого компонента из армированного стекловолокном нейлона на Композит из длинноволокнистого стекловолокна PA6-LGF40 в позиционирующем упоре станка для резки алюминиевого профиля.

Модернизация не только улучшила механические характеристики и долговечность, но и является примером практического применения « пластик заменяет металл " и " длинное волокно заменяет короткое волокно «Концепции компонентов промышленного оборудования, обеспечивающие как технико-экономические преимущества .

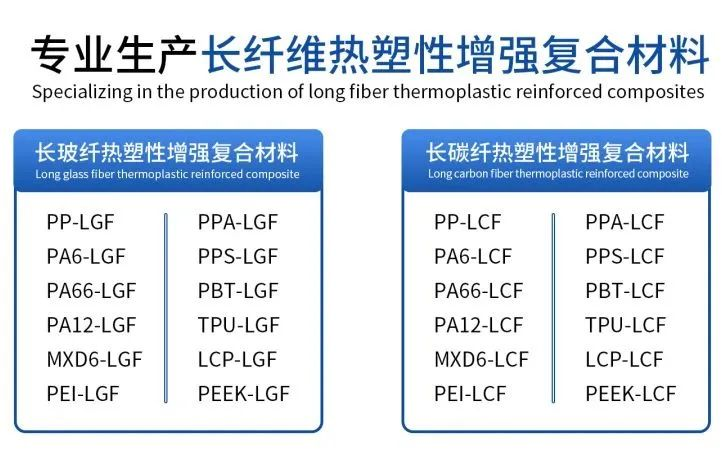

Компания Xiamen LFT Composite Plastic Co., Ltd. (LFT-G) — ведущий мировой производитель термопластичных материалов, армированных длинными волокнами (LFT). Наш отдел исследований и разработок специализируется на исследовании, разработке и производстве высокоэффективных композитных материалов, включая полиамид (PA), полипропилен (PP), термопластичный полиуретан (TPU), полиэфирэфиркетон (PEEK), полифениленсульфид (PPS) и полиакрилонитрил (PPA), наполненных длинными стекловолокнами или углеродными волокнами.

Наши материалы широко применяются в автомобильной промышленности, электронике, электроинструментах и промышленных компонентах, предлагая исключительная прочность, ударопрочность, размерная стабильность и «пластиковая замена стали» возможности.

Стремясь к инновациям и устойчивому развитию, компания LFT-G объединяет передовые технологии с клиентоориентированным обслуживанием, предлагая индивидуальные решения, отвечающие самым высоким требованиям, при этом снижая вес, повышая долговечность и обеспечивая экономическую эффективность.