новый блог

â Что такое композит, армированный длинными волокнами (LFT-G)?

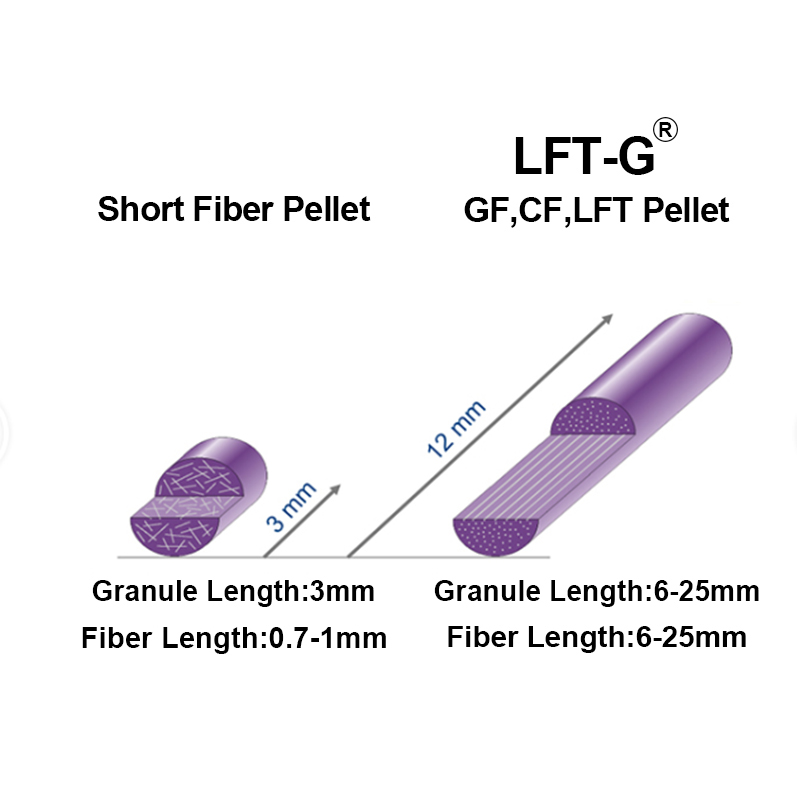

Включенная длина армированного волокна эквивалентна длине пластиковых частиц термопласта размером более 6 мм.

â Каковы преимущества использования LFT-G?

Преимущества для владельцев бизнеса и заводов:

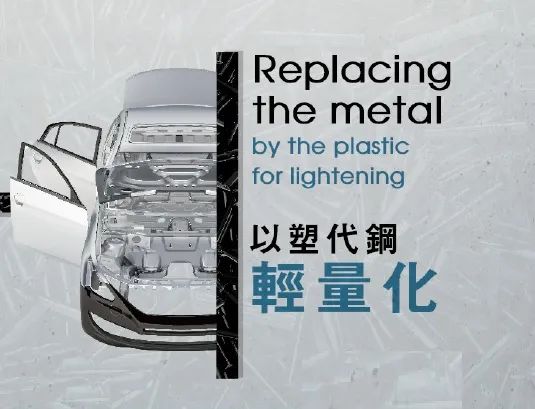

а. Пластик вместо стали: прошлый металлический материал с высокой прочностью, термостойкостью и другими характеристиками является предпочтительным материалом для многих промышленных изделий, но его недостаток не подходит для формирования сложных форм. Материал, армированный длинным стекловолокном (L.F.R.T), по своим свойствам наиболее схожий с металлом, кажется лучшим выбором для замены металла.

б. Легкий вес: поскольку вес обычных металлических деталей относительно велик, в связи с тенденцией защиты окружающей среды/энергосбережения в развитых странах мира в отрасли началась тенденция «облегчения».

в. Высокие механические свойства: в деталях, изготовленных из LFRT, длинные волокна образуют трехмерную трехмерную сетчатую структуру внутри и проходят через матричную смолу в качестве армированного каркаса, поэтому детали могут выдерживать большие напряжения и нагрузки и эффективно поглощать внешние воздействия. энергия удара, благодаря чему готовые изделия обладают превосходной удельной прочностью, жесткостью, ударопрочностью, стабильностью размеров. А также термостойкость, низкая деформация, сопротивление ползучести, низкий коэффициент теплового расширения и другие преимущества.

â Использование LFT-G для защиты окружающей среды

В отличие от обычных термореактивных материалов, LFT-G представляет собой термопластичный материал, и его отходы могут быть переработаны и измельчены, а также повторно использованы или смешаны, производительность не будет значительно снижена и может снизить стоимость утилизации отходов по последнему разделу.

â Каковы преимущества использования LFT-G? Каковы льготы для сотрудников?

По сравнению с обработкой металлов/термореактивных материалов, LFT-G является материалом с низким содержанием летучих органических соединений и не выделяет токсичных веществ.

â Каковы преимущества LFT-G по сравнению с продукцией других компаний?

а. Компьютеризированная/автоматизированная оригинальная технологическая установка европейского стандарта, стабильное качество, отличное покрытие между смолой и волокном.

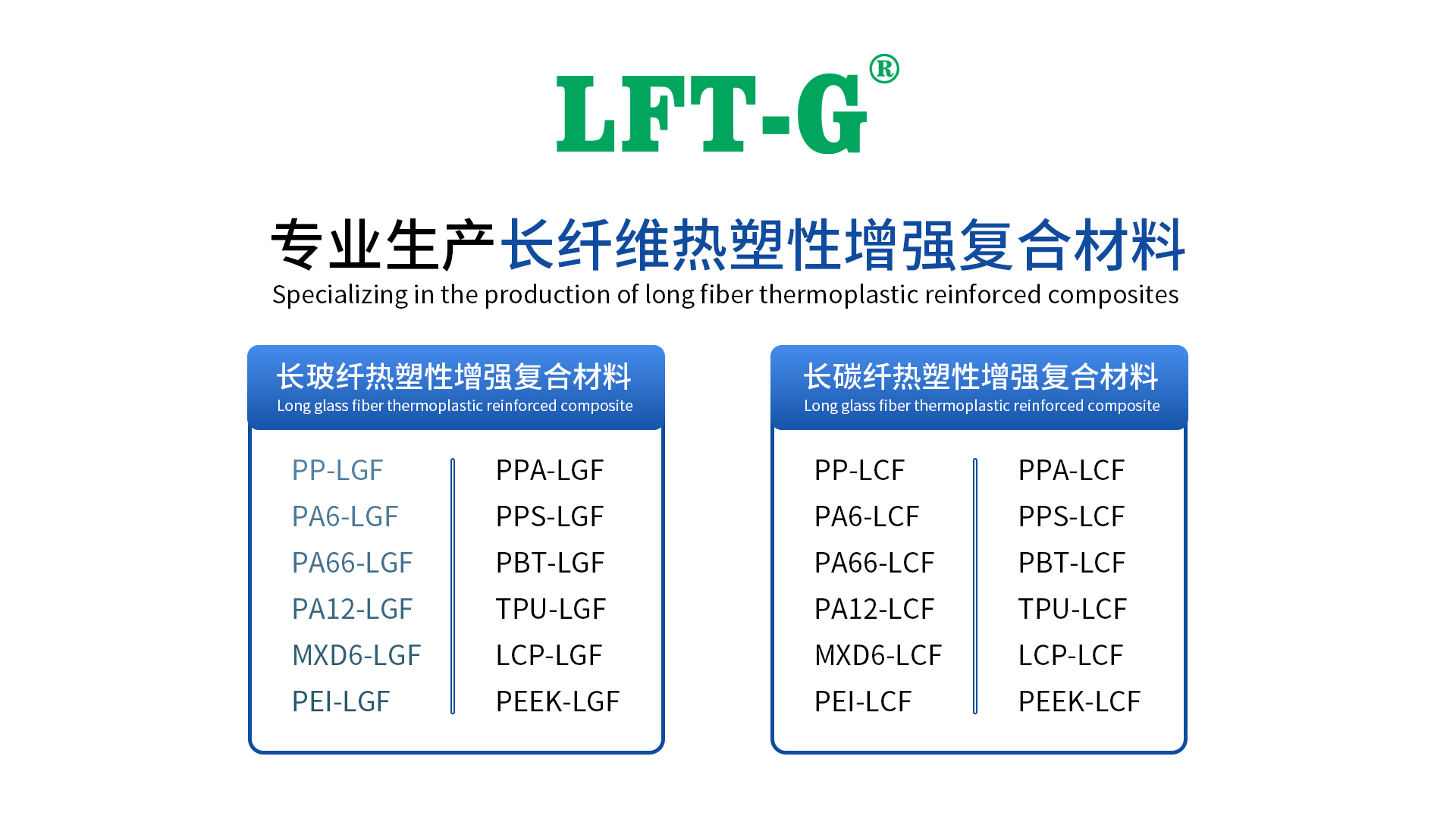

Б. разнообразие продукции, включая ПП, ПА6, ПА66, ТПУ, ПА12, ППС, ППА и другие материалы.

в. Команда технической поддержки Dadong поможет клиентам решить соответствующие вопросы на протяжении всего процесса, такие как предложения по спецификациям, параметры обработки, формы, применение продукта и т. д., чтобы гарантировать, что характеристики материалов могут соответствовать требованиям клиентов.

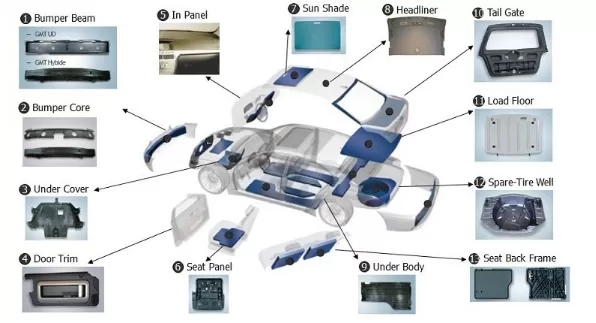

â В каких отраслях можно использовать LFT-G?

Подходит для автомобильных деталей, ручных инструментов, спортивного инвентаря (велосипедов/лыж/рыболовных снастей), деталей обуви, промышленных вентиляторов и других отраслей промышленности.

â Будет ли использование LFT-G стоить дороже?

а. Цена за единицу материалов немного выше, чем у алюминиевого сплава, но это позволяет сэкономить затраты и время на вторичную обработку металла, что в целом является относительно выгодным.

б. Цена за единицу материалов немного выше, чем у однородных композитов, армированных штапельным волокном, но LFT-G обладает высокой стабильностью размеров и не поддается деформации. Его можно собрать после извлечения из формы, что позволяет сэкономить время охлаждения/выдерживания давления при формовании и затраты/время на установку индивидуальных инструментов.

â При использовании формованного изделия LFT-G будет плавать волокно?

Выбор смолы Datong для смоляной подложки - это смола с высокой подвижностью, внешний вид готового продукта хороший, при температуре формы производительность лучше.

â Использование LFT-G приведет к большему износу винта литьевой машины?

Изнашиваемый винт в основном представляет собой острое поперечное сечение на обоих концах волокна. Длинное и короткое волокно имеют двухточечную и однолинейную структуру, но в одинаковой пропорции площадь острого поперечного сечения короткого волокна больше, чем у длинного волокна, поэтому износ обоих винтов на винте аналогичен.

Благодаря приведенным выше вопросам и ответам узнали ли вы больше о композитном материале LFT-G, армированном длинными волокнами? Если вы хотите узнать больше, пожалуйста, свяжитесь с нами.